For those of you who make bows, arrows, or any other thing of wood, you probably do a lot of sanding. I’ve had a few sanding blocks in my time, purchased from lumber stores with great enthusiasm. The enthusiasm generally wanes when I find I have to cut the sand paper to fit the block, or when the clips that hold the block fail, or by finding out I just don’t like how it feels in my hand.

So, I made my own out of some scrap wood and it has worked really well. Once I got the kinks worked out, I made a few extras so I wouldn’t have to switch paper to change grits. The cost was right, too.

So, I made my own out of some scrap wood and it has worked really well. Once I got the kinks worked out, I made a few extras so I wouldn’t have to switch paper to change grits. The cost was right, too.

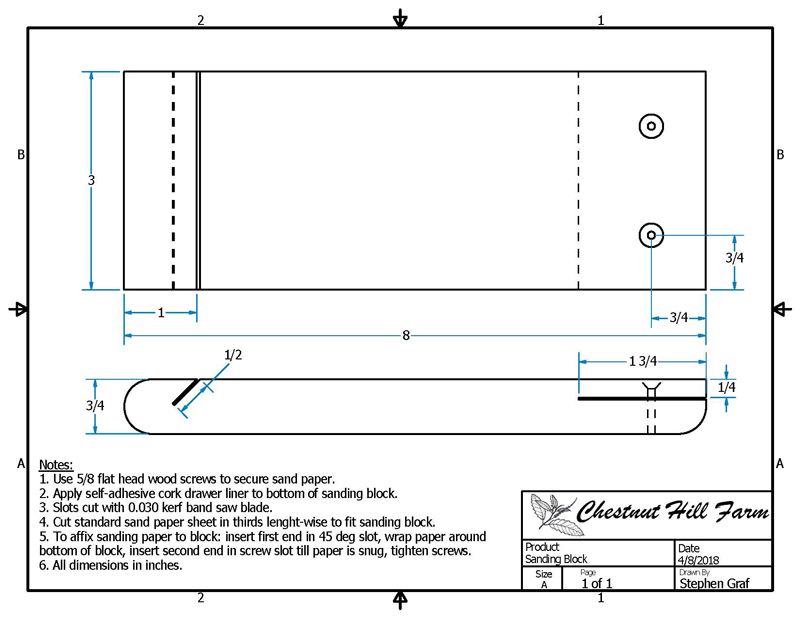

- Cut a wood block 3” x 8” x ¾”.

- Using a band saw or hacksaw, cut a ½” slot at a 45° angle 1” from the front, and another slot across the back of the block ¼” from the top and 1 ¾” deep.

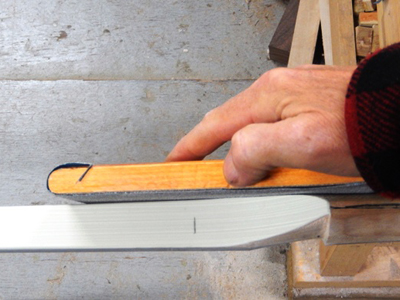

- Apply self-adhesive cork drawer liner to the bottom of the sanding block.

- Round the front and back edges of the block so the sandpaper rolls smoothly around it.

- Cut a standard sheet of sand paper in thirds length-wise.

- Insert one end of the sand paper into the 45° slot, wrap the paper around the front and bottom of the block, and insert the second end of the paper into the screw slot until it is snug.

- Use two 5/8” flat head wood screws to secure the paper.

(Link to a larger pdf: http://tbmdownloads.s3.amazonaws.com/SandingBlock.pdf)

Editor’s Note: Steve Graf knows a lot about woodworking and building “bows, arrows, or any other thing of wood.” His recently published book, The American Longbow: How to Make One, and Its Place in a Good Life can be found at 3Rivers Archery, Amazon.com or Barnes and Noble.

On the desk calendar today a poem by John Keats.

“A thing of beauty is a joy forever”.

Looks pretty nice, Steve.

Just like Steve’s book, The American Longbow”, his sanding block is a great addition to the wood shop. Steve’s book is a source for amazing tips, plans and knowledge, and the sanding block is easy to make and really gets the job done! Try it you’ll like it.

Since this tip was originally posted, I made an improvement to the sanding block. Grabbing a screw driver to loosen/remove the paper was a bothersome step, so I changed the screws out.

Instead of flat head wood screws going down into the block, I installed some flathead machine screws coming up. Then I put a washer and brass thumb nut on the screw. Now it’s just a matter of loosing the thumb nut to replace the sanding paper.

I made several sanding blocks from walnut and find that the weight helps the sanding process.

I keep a sanding block loaded with each grit I need on a project so I don’t have to switch out paper till its worn out.