The more I learn about primitive people the more amazed I am at their intellect, skill, and ingenuity. Regardless of how advanced we become, stone age people still have things to teach us. In this article we will explore another possible example of their engineering that could have resulted in high-performance primitive bows capable of matching and even surpassing the performance of our modern fiberglass longbows and recurves.

Keith’s sinew backed fire-hardened bows are as beautiful as they are deadly.

Early Spanish soldiers exploring the Southeastern U.S. wrote about the incredible power of the bows used by the Native Americans they encountered. White woods like elm, oak, and hickory (among others) were noted as being used for bows by many Eastern tribes. It’s likely many of those bows were made of hickory, because it’s widespread, hard, and almost unbreakable. However, its affinity for absorbing moisture has a detrimental effect on performance. Humidity is fairly high in this region for most of the year, soaring to 75% or more during the summer. This can cause a noticeable performance loss for a hickory bow in those conditions. I know because my own hickory bows have fallen victim to this humidity and suffered a noticeable drop in performance. How could the Eastern tribes have maintained high performance weapons in such humid conditions without synthetic sealants or dehumidifiers?

The ancient technique of fire-hardening a bow was accidentally rediscovered by primitive archer and inventor of the Bug Tamer suit, Keith Shannon. He was fascinated by the accounts written by early explorers describing the power of the bows wielded by the Native Americans in the Eastern U.S. He was also amazed how they used fire in every aspect of their daily lives. In addition to warmth and cooking, fire was also used to make pottery, smoke buckskins, preserve meat, provide light for night hunting, clear underbrush, heat treat flint, and even fell large trees. Fire was then used to burn out the center of that tree to make a dugout canoe or used on a smaller scale to make wooden serving and storage bowls. Wooden digging implements and wooden arrow points were fire-hardened to improve their performance and longevity.

The use of fire to reduce wood peaked Keith’s curiosity…could it have been used to make a bow? Written accounts never mentioned it, so he decided to give it a try. Keith first used a small propane torch to burn the belly wood off a seasoned hickory bowstave. Once the wood became scorched, he scraped the charred wood away with a small flint flake. When the scraper hit the hard wood, he simply applied more flame to burn off additional wood and then scraped away the char. By repeating this technique, he was able to remove a substantial amount of wood with surprising speed and greatly reduced physical effort. Instead of hacking the wood off with repeated blows from a hatchet, he let the fire do the work and he just scraped away what remained.

Keith fire-hardens a hickory bow blank over a bed ofcharcoal briquets. Constant monitoring is required toprevent overcooking the wood.

Once the bow stave was close to the finished dimensions, Keith then used modern hand tools to remove the remaining belly wood and begin tillering the bow. But the moment the tools touched the wood he noticed a profound difference. The now discolored wood was hard. The shavings didn’t peel off in flexible curls as he was used to. Instead, the shavings were thin, hard, and brittle. When he switched to a rasp, the wood resisted its teeth and the chocolate-colored chips of scorched wood that were removed were very dry—and very hard. It was obvious the wood had been fire-hardened. As Keith tillered the bow and thinned the limbs, he was amazed at how deep the hardening went. The prolonged heat had penetrated halfway into the wood, signifying a profound structural change. But how would that affect the bow?

As wood is heated, it becomes brittle. There was a chance the wood’s flexibility had been so compromised that the bow would explode if bent too far. But as tillering progressed and the limbs were subjected to increasing strain, the bow held together. The hardened belly wood made the bow surprisingly resistant to bending, while the wood on the back was unaltered. The combination made the bow very springy and responsive. After careful tillering, the bow settled into its final draw length and never cracked, splintered, or showed any sign of failure. After shooting the bow, Keith realized this was unlike any wooden bow he’d ever made before. It was fast. But even more amazingly this bow showed no string follow, which is almost unheard of when making a bow from hickory.

For the next two years, Keith quietly experimented with different bow designs and different fire-hardening methods. Every time he fire-hardened a bow, he saw dramatic improvements in both arrow speed and moisture resistance. He made unbacked and sinew-backed versions and had great success with both. Fire-hardening had changed hickory so that it behaved like a different type of wood. What exactly was happening here?

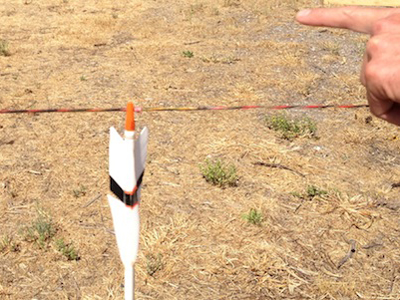

Keith shoots a fire-hardened bow through a chronograph to clock its speed. These tests have proved the performance of fire-hardened bows.

Internet research turned up some interesting information. Fire-hardening makes wood structurally stable, meaning it resists twisting, warping, swelling, or shrinking, even in high humidity environments. Fire-hardened wood becomes hydrophobic, meaning it won’t absorb water nearly as readily as raw wood and it expels that moisture very quickly when humidity levels drop. Fire-hardening makes the wood more resistant to rot and also reduces its attractiveness to wood eating insects like termites and wood borers.

Fire-hardening a bow’s belly enhances its performance in several ways. It hardens the wood precisely where it’s needed most—the belly. The hardened belly is now more resistant to compression, making it snap back to shape faster, resulting in higher arrow speed. This increases a bow’s draw weight by as much as 25%, making it store more energy without adding mass or weight. Fire-hardening a bow into a certain shape “sets” that shape into the wood. This means fire-hardened staves can be clamped into a variety of forms, including the popular reflex/deflex design, and that shape will hold. Even twisted staves can be clamped to a form, fire-hardened, and when cool the stave will mirror the form perfectly and the twist will be eliminated. Even old white wood bows with average performance and string follow can be given new life by reflexing the bow in a form and fire-hardening the belly. The bow will enjoy a substantial increase in draw weight, greatly improved moisture resistance, and noticeably faster arrow speed.

Fire-hardening isn’t a quick process. It requires prolonged heat over an extended period of time. This low and slow cooking allows the heat to penetrate deep into the wood and plasticize the wood cells deep into the bow. Different wood species tolerate different degrees of fire-hardening and adjustments in time and temperature must be made depending on the species. The hotter the fire, the less time that’s needed to fire-harden a bow. But don’t overdo it, for the wood will burn and ruin the bow.

The best candidates for fire-hardening are tension-strong woods that lack compression resistance. North American white woods like elm, white oak, dogwood, hickory, and sweetgum, among others, respond very well to fire-hardening. Based on our experience, hickory is one of the best for fire-hardening. It is incredibly strong in tension and can tolerate some fairly intense heat and still make a fantastic bow.

The browning on the bellies of Keith’s bows indicatesthey are fire-hardened and possess hydrophobic qualities.

Unfortunately, fire-hardening doesn’t really improve Osage orange or dark exotic woods from the tropics like ipe. Those woods are more naturally moisture resistant and better able to resist compression due to their hardness. But fire-hardening tension-strong North American whitewoods can result in dramatic performance improvements. Fire-hardening transforms “second rate” whitewood bows into top-tier performing weapons capable of matching and even outshooting some of the best Osage self-bows and fiberglass traditional bows.

Whether this technique was used in the Stone Age is unfortunately lost to history. But Keith believes that at least some ancient people figured it out. Perhaps they used fire to remove wood just as he did and stumbled onto the same results. I have to agree. I find it hard to believe that some ancient people with unbroken generations of knowledge didn’t discover this technique in the distant past.

Keith also torture tested different fire-hardened bows to see how much abuse they could withstand and to determine the limits of fire-hardening. Tension strong woods like elm, hickory, and white oak did very well and survived mild overdrawing with no set or performance loss. As stated earlier, fire-hardening makes wood more brittle, but bows of tough white woods can sacrifice some flexibility and still remain reliable and durable hunting weapons.

After numerous experiments proved fire-hardening produced consistent, repeatable results, Keith decided to release this concept to the bow-making community by producing a video. He then contacted primitive archer Thad Beckum and me about producing a DVD. The three of us agreed to meet and see these bows in person.

This fire-hardened, sinew backed hickory bow holdsan astounding four inches of reflex. No raw hickorybow could retain this profile.

Of course, I was skeptical of the claims—until I saw the process firsthand, examined the bows’ reflexed profiles, and actually shot them. I was really impressed with the results. They are fast, efficient, and free of hand shock, and they retained impressive reflexed profiles, something I’d never seen in a hickory bow before. They also resist moisture absorption and suffer no performance loss even in stifling humidity. Chronograph tests proved they can match and even exceed the performance of top-rated modern fiberglass longbows and recurves pulling the same draw weight. I knew Keith was onto something big. After several months of filming and editing, we released this concept to the world in a DVD.

The Art and Science of the Fire Hardened Whitewood Bow DVD was released in December 2019. The video shows the entire process from cutting down the tree, to reducing it to a blank, fire-hardening both a straight and reflexed stave, and final tillering. The video delves into the science of fire-hardening, shows how these bows could have been made easily by stone age people, and finally concludes with a successful deer hunt using a fire-hardened bow.

Every bowmaker who’s followed Keith’s methods has produced weapons of stellar performance. They confirm the same results we’ve had—high performance, moisture resistance, hydrophobic qualities, and low set with fast, flat arrow trajectories. Fire-hardening elevates common woods into superior, fast shooting bows that can go toe-to-toe with the most expensive fiberglass bows of today.

He has done a favor to all who make bows . This is truly a step to match most store brought bows. Thanks and God bless.