Home › Forums › Friends of FOC › AMAZING!!!!Thank You Mr. Ashby!

-

AuthorPosts

-

-

If any of you read my post from a couple weeks ago, you know I’m working on building my son a “super” arrow for his short draw and low draw weight bow.(He’s 14,but has a 23″ draw shooting 40 lbs.).

Well, today I finally got all the components together and we were tuning/testing. I have two shafts each of 500, 520, 570, 630, 700, and 750 spine “skinny” arrows. They consisted of VAP’s, Beman Carbon Flashes, and the now discontinued (a shame, it was a great shaft)Beman Carbon Racings. All shafts have a diameter between .215″ and .218″. Weights with the custom outserts and 145 gr. field points were between 360gr. and 415gr. My goal was to find a shaft with UEFOC that came in between 400-425 grs.

Well to say it went well would be a gross understatement! The penetration he was getting was UNBELIEVABLE!!! It actually became a pain stacking backstops together to stop these things! Here’s his first shot (untuned) with a bare shaft at 10 yds. :

-

We quickly ruled out the 500 and 750 spined shafts. However, ALL the others were flying very well. Very little wobble or wagging could be seen with the naked eye out to 25 yds. He was shooting groups of about 3.5″ at 20 yds. with all the rest of the shafts. I don’t mean each spine, I mean shooting all of the diferent spined shafts into a group at 20 yds. ! These shafts, with all that weight up front, flew like darts.

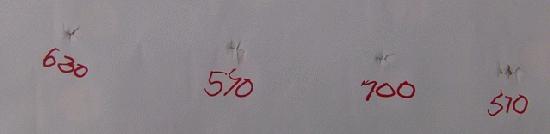

We finally had to break out the paper to see which shafts actually were flying better. This is the results:

-

I should mention… we shot thru paper from 10 yds. to 40″ away from the face of the paper. We had to keep moving closer because there just was no discernible difference in the tears! The above photo shows what we found when the paper was 40″ in front of his arrow. The 570 showed a slight wag to it (so we eliminated it), but the 630 and 700 look dandy!

I should mention at this point the problems we had with “containing” these little beasties. That first shot on the left went through 11.5″ of virgin styrofoam, 2″ of ethafoam, and 13″ of a multi-layer Cabelas foam target. The arrow finally stopped when it hit the 2nd to last layer of very dense, hard foam in the rear of the target. I should also mention that none of these targets are “shot out” (the ethafoam has been shot very little actually) and we purposely positioned the targets so he would hit away from the center and into virgin or less shot areas of the targets. Honestly, pulling arrows was a pain.

After seeing the tears with 630 and 700 arrows we walked back to 20 yds. We had the styrofoam set up with the 2″ ethafoam immediately in back of it. My son let loose with the 700 and all I saw was a slight flash of yellow (nock) and I heard the slight “thuk” of it hitting the styrofoam. I told him to shoot the 630… I heard “thuk” “WHUMP” ! What the heck ? We walked up to see this:

-

Both arrows passed thru the 11.5″ of styrofoam target and 2″ of ethafoam like it wasn’t even there! The “whump” we heard was the second arrow burying itself into the wood frame we have at the base of our target area. The penetration we were seeing was nothing short of amazing! I’ve shot both these targets before with conventional arrows in the 400-500gr. range out of a 59# bow and have NEVER got penetration like this. ( I should mention that my arrow flight was likely not near as perfect as his either). We kept walking back a fes yds at a time with the same results.

Finally, at 30 yds, the arrows stopped in the target. The 630 was the deeper one, penetrating the whole 11.5″ of styrofoam and 2″ of ethafoam with the point and outsert sticking out the back. The 700 penetrated the styrofoam and just the tip of the field point stuck in the ethafoam.

-

Munsterman, thanks for these enlightening posts. Yet more evidence of the counterproductive obstinance of those who insist on the mantra “if it ain’t broke, don’t fix it.” If we’re not shooting through animals consistently, something in fact IS broke, and the Ashby Penetration and Lethality Study has the fix! Now your young son, with his short draw and low-poundage bow, can hunt with confidence. 😀

-

He shot several more arrows and sometimes they would be stopped by the targets, sometimes not. Anything closer than about 25 yds. and they were going right thru.

The 630 shaft came in at 392grs. and 29.5% FOC . The 700 shaft came in at only 360 grs. ,but 33% FOC. Neither of them hit the 400 – 425 grs. I was hoping for, and the 630 didn’t quite make UEFOC 😥 . However, both fly like absolute darts:D . My son even commented that these bare shafts fly better than his 3D arrows.

We chronograph-ed both arrows and he’s getting 168 fps out of the 630 and 174 (if I remember correctly… we chrono-ed all of them) out of the 700’s.

Sorry for the long-winded posts, but to say I was impressed and excited is an under-statement. I know my setups will be changing for myself after seeing this. After talking with a buddy and telling him the results… I think his might be too!

Tomorrow it’s fletching and broadheads! May the best arrow win. ( I’m rooting for the heavier one)

On a side note:

Thank you Mr. Ashby for your life-long study and sharing that benefits us all. The bowhunting community truly owes you a debt of gratitude. It’s my fervent hope that more people will read your work and then try it for themselves so that they may be convinced of its efficacy.

-

Ready for more testing today:

-

I’m loving it!!! I’m already into the season and a little late for me to change my daughters setup. She is shooting confidently right now and I dont want to change a thing. She’s shooting some nice 26″ POC with a 130grns Zwicky….

Munster, you’re doing some nice work there

-

Broadhead tuning was uneventful. Broadheads shot to the same point as field points for both spines and both spines shot to almost the same point( the heavier 630’s shot about 3/4″ – 1″ lower, but dead in line, no L/R difference at all).

These things really do penetrate though:

After this we put some space between the targets and it seemed to help.

Now I’m left with the decision of which arrow… the 700’s at 362 grs. and 33% FOC or the 630’s at 392 grs. and29.5% FOC. The 700’s are faster by 6fps and shoot extremely clean, but the 630’s shoot just as well I feel and definitely have the advantage of weight. I’m leaning toward the 630’s.

On a side note: I stood on the deck while my son shot… you really can’t hear the fletch of these arrows ! You can see in the photos that these have a slight helical ( didn’t have straight clamps – I kept them as straight as possible and still get good contact between fletch and shaft, but it didn’t seem to matter much on these short fletch). I went with 2.5″ 3 fletch ( not much room on these thin shafts for 4 fletch) with the hope it would be enough to stabilize the broadheads. In retrospect, I think I could have went with 2″… there were no stability issues whatsoever. Broadheads grouped right with field points which grouped with bare shafts.

-

Shouldn’t be a problem with either shaft. The weight vs FOC is a close race.

Like you I might lean to the heavier shaft since it is just under UEFOC.

Thumbs up for the great work and time involved in tuning instead of letting in the usual “Thats good enought” become part of it.

Troy

-

Fantastic report, congrats on your hard work panning out.

This reminds me of when I first shot compounds. I shot a 50lb High Country Supreme. it was a short axle to axle 2 cam bow. I only mention that on this forum, cause when I first started shooting it all I had were fat aluminums, real fat. Later I bought some real skinny (do not recall arrow size) carbons. They were pretty new to the market than, and they came with outserts. These were NOT EFOC arrows, but when I shot them into my foam deer target, they blew right through. I knew the little bow packed a bit more energy, but this was odd, so I thought, then someone else told me it was the outserts. They open a hole and the arrow has so little resistance it blows right through.

I think that is what you are seeing here, and I bet it works the same on game animals.

I will be looking forward to seeing hunt results. Good luck to your son.

Were those using the brass outserts?

-

handirifle wrote:

Were those using the brass outserts?

No, aluminum. The brass would have made the whole arrow too heavy for a 40# bow woth 23″ draw. I did add some lead to the points though. Total point weight , if I remember, was about 220-230grs. ( that’s on a 360-392 gr arrow that’s 24″ long).

-

Looking back at your pics, now, I see the aluminiums. Incredible results.

Let me ask you this. If you owned the CNC machine (you might, I am just surmising) how would you go about calculating cost per unit? I know the huge cost of the machine, the programing time, usable tool bits, and materials are in play, but how in the world does a shop figure out how much to sell those things for?

Materials, and time are easy, but how do they factor machine cost and wear and tear?

-

handirifle wrote: … but how do they factor machine cost and wear and tear?

We have fixed rates for hours (actually minutes) a machine runs. In reality, they’re not fixed, but a close average over time of what it costs to run these machines. That with material, time, tooling and profit margin = quoted price. Then you cross your fingers and hope you don’t run into any unforeseen problems that blow your estimation out of the water.

When speaking of products like this, margins are low, so it’s important to be running them on the most efficient machines for the job. Numbers of parts plays a huge role in final price as well. You can make 10K parts a WHOLE LOT cheaper than 10 parts on a per unit basis.

Oh yeah… I don’t own these machines. I have owned a toolroom CNC before and I can tell you… they’re expensive if you don’t keep them spitting out parts.

-

Yea I kinda assumed you didn’t own it, but figured you did know how they price em out. I am aware that volume makes a huge difference, that applies to many types of manufacturing.

Am glad to see you getting to use it, especially for your son’s hunting. Still you give folks a great understanding of how the kids can still be very effective, with the lighter weight bows and short draws.

I always go back to thinking how effective the old English war bows were at penetrating armor and shields, with those iron tipped arrows.

-

-

AuthorPosts

- You must be logged in to reply to this topic.